|

Rack and pinion

收藏

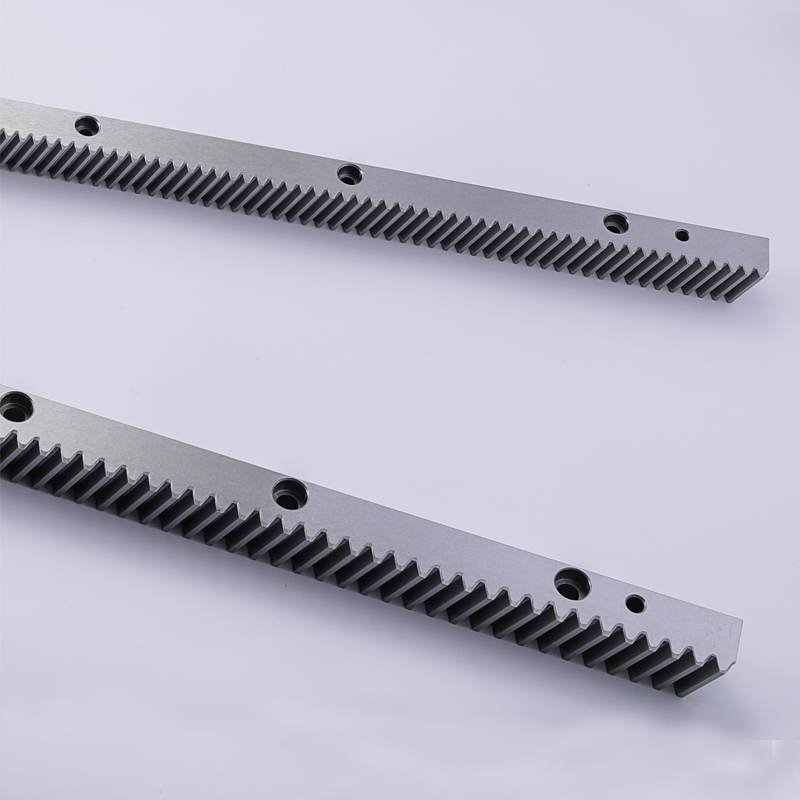

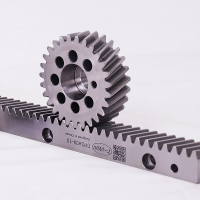

1. Definition: It can be divided into positioning rack and transmission rack (the main production positioning rack of table stable t-win). Generally, the positioning rack has high precision and can be precisely positioned. Generally, the transmission rack has low precision, which is only used for the purpose of transmission if the requirements are not high. 2. Classification: It can be divided into straight teeth and helical teeth. The advantages of helical teeth are smooth walking, large transmission torque, which is 2.5-3 times larger than that of straight teeth without increasing module. From the processing technology of fine milling, gear shaping, grinding; heat treatment process normalizing, tempering, high-frequency quenching. Material: generally, 45 steel is used, and 42 chrome molybdenum can be used for those with higher requirements. 3. Application industry: Large stroke gantry machining center, optical fiber cutting machine, numerical control woodworking machining center (carving machine, numerical control drill, electronic saw), automatic production line, truss, ground rail robot, and some linear motion industries that are not suitable for using lead screw transmission. Our company is mainly engaged in small and medium-sized positioning rack, with modulus between 1.25-4, mainly facing woodworking industry, optical fiber cutting industry, automation, ground rail and other industries. 4. Advantages analysis of gear rack: Rack precision is high, standard grinding precision can reach din6, straightness is within 0.03. The product is made of 45 steel with high rack hardness and special material. The product has high corrosion resistance. The helical rack has high torque and higher output power. We can customize according to the gear drawing, and also provide technical drawing support.

|